Technological innovation for the viticultural industry

In this project our global program students examined the working practices of famers in the French viniculture industry. They ultimately developed a unique solution to problems related to pesticide application.

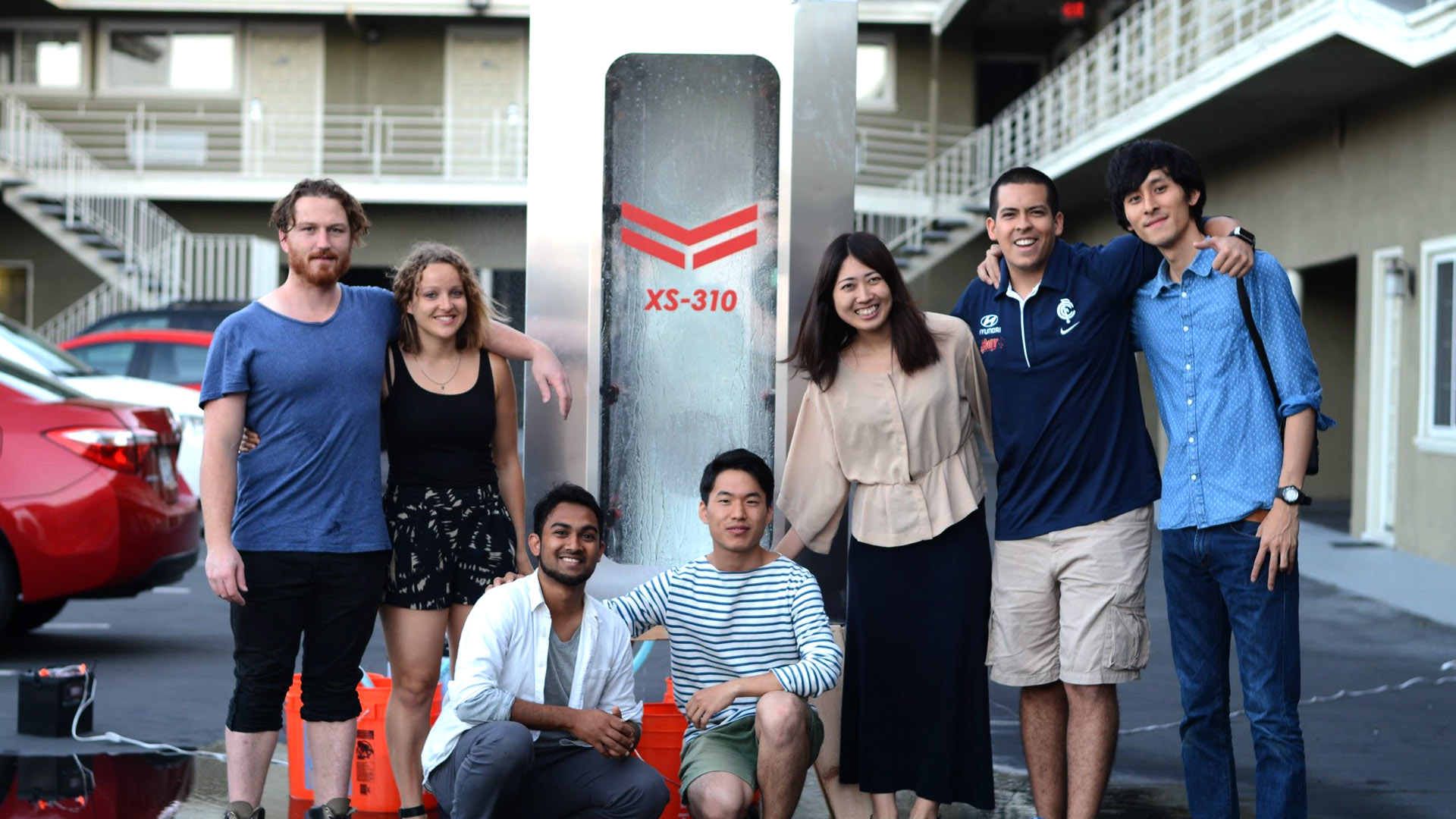

The team was made up of students from Kyoto Institute of Technology, Japan, and students from Design Factory Melbourne, who worked in close collaboration with the industry partner Yanmar from Osaka, Japan. DFM was identified as an ideal partner for this project due to Australia’s rich viniculture industry and for the design expertise needed. The solution was ultimately identified as implementable by Yanmar and has been taken further into R&D with the goal of commercialization.

2021 Commercialization Update: See Yanmar’s new product in the market here.

The client: Yanmar

Yanmar tasked the team with investigating the French viniculture industry. They believed that French vineyards have stayed more traditional and less mechanized than those globally. Yanmar saw an opportunity for a new market here and wanted to understand the sector better.

The Problem

They found that the problem went deeper than a technological solution. In order for the technology to be accepted by farmers the machine needed to address their needs including cost effectiveness, higher efficiency, lower environmental impact both on the farm and for the wider community.

Solution

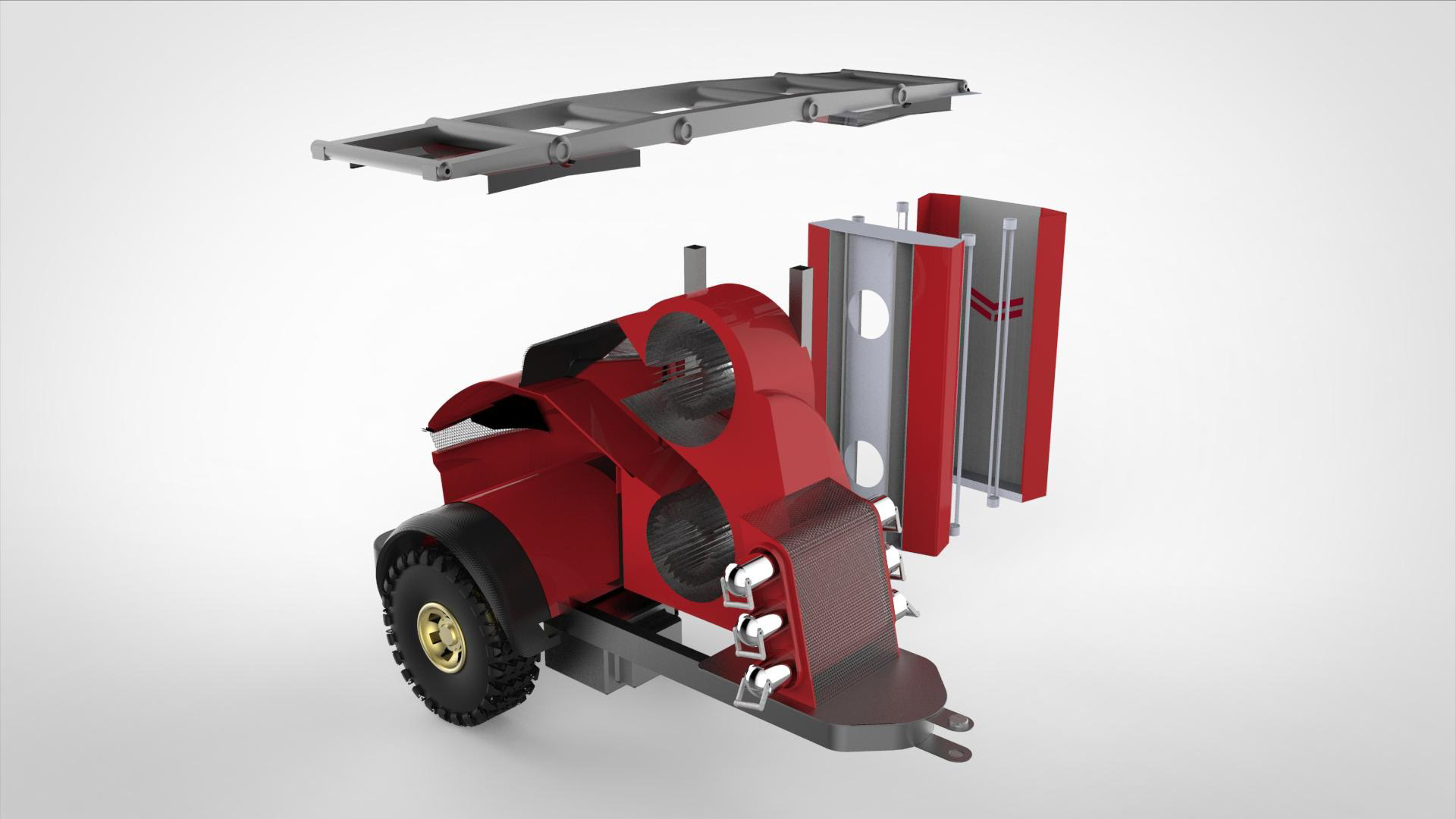

The team produced a lightweight maneuverable sprayer that used ground-breaking processes to apply pesticides in a manner that was faster, more effective, cost efficient and environmental. The machine, although developed for use in French vine-yards has global application.

The team also produced research outcomes related to maneuverability of machines in vineyards on steep slopes that was combined with other projects that Yanmar were working on. As well as concepts for software which tracks weather data and pesticide application.

Process

Focusing on crop-spraying meant validating the existing team’s sprayer concepts through analysis, prototyping, and advice from specialists—particularly on spray systems and fluid dynamics. In doing this the team developed strong relationships with farmers through a co-creative process of integrating, drawing, and prototyping with and alongside farmers to directly include them in the outcome.

The results of the research were incorporated in a single machine with mechanical, physical and digital, and performance properties identified as crucial needs for vineyard farmers.

User Needs:

Drivers/Problems:

The solution needed to consider the speed effectiveness and efficiency of spray systems for farmers. This would improve costs for farmers. Research identified that pesticides work best when they are applied from many directions. The size of the droplet is also a consideration in effective crop-spraying and is highly dependent on weather conditions such as wind speed and humidity. These considerations needed to be present in any design solution.

The team identified pesticide drift as a major issue for farmers in crop spraying. Sprayed pesticides become airborne and are a threat to human health and wildlife and ecosystems in agricultural and residential areas. They are particularly hazardous for farmers when spraying. There are additional emotional costs for farmers identified due to the growing social pressures to farm in a way that is more environmentally conscious.

Design details

The XS-310 is more efficient at crop spraying as the system can achieve an effective coverage of the crops with one pass, whereas current systems require two. It is small and maneuverable, designed to be attached to a traditional tractor ensuring it will fit into current vineyard practices. The reduction in both pesticides used and spraying time address key issues for farmers.

An additional digital platform has been developed that maps where the sprayer has been within the vineyard. This allows farmers to record spray levels live, which collects data that is legally required for accountability.

The project resulted in a global patent being filed and the XS-310 has been taken into further research and development by Yanmar with plans to commercialise the technology.