Swinburne Design News

Design Factory Melbourne Concepts Protect the Planet and Improve Health

Belinda Stening Contributing Editor

16 May 2018

This article was originally published in Swinburne University of Technology’s Design News – a platform celebrating design and innovation across Swinburne’s School of Design. Discover the latest design news about Swinburne’s research, teaching and student success stories.

An initiative of Design Factory Melbourne, the A3 Challenge Based Innovation Program or A3 CBI is run in partnership with IdeaSquare and The European Organization for Nuclear Research or CERN, in Switzerland, and Design Factory Global Network partners.

Over six months, Swinburne Honours and Master of Design students work in the A3 CBI program. They are challenged to apply CERN’s lab-based technologies to design innovations. The design solutions need to be sustainable, benefit society and have proven commercial viability.

Concepts address the United Nation’s Sustainable Development Goal 12 – Responsible Consumption and Production. This year, two teams from Design Factory Melbourne, Team ATMA and Dasein designed concepts for 2020, 2025 and 2030.

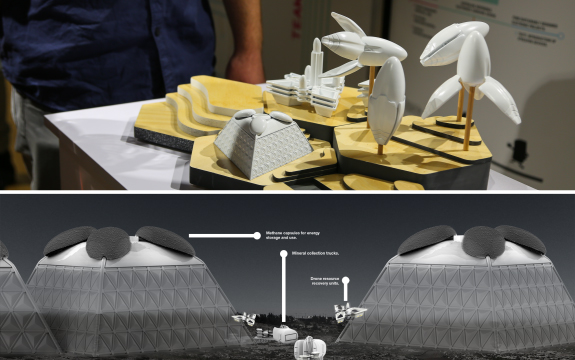

Scale models and concept illustration of e-waste mine site and drones

“Team ATMA’s goal is to design a more responsible way of managing the disposal of electronics in Australia. Their concept has a strong focus on metal recovery and value,” explains Associate Professor Christine Thong.

Digisave mines, recovers and sorts electronic waste. Metals are recovered rather than wasted. Components from electronic devices are fed back into the system where possible.

“By 2030, the ultimate goal is to provide a digital presence in a new form that is tactile, and unique to how data presents itself in software. The TACTI device concept tackles the future vision of the personal device. It questions how smartphones might evolve or even disappear in the future,” says Associate Professor Thong.

TACTI, next-gen mobile personal programmable device

Team Dasein’s Metaphor concept consists of two sub-concepts. The first is Metaflora for hospital patients on a normal diet. It reduces food waste in hospitals by onsite composting, cultivation and harvesting of fresh produce.

“It’s a modular hydroponics system connected to the data ‘hive’ of a hospital. A dynamic system, that grows plants to order. It creates an equal ratio of food supply versus demand, with zero waste,” explains Associate Professor Thong.

Metaflora, bladeless drones manage crops inside closed-loop self-sustaining hydroponic farms

Metaflora have modular hyrdroponic rings, attached to a central water pipe. The pipe dispenses liquid fertiliser into the rings and onto crop root systems through small nozzles.

Plants are grown in compost pucks, made from hospital food waste. Bladeless drones plant, care and harvest crops inside the closed-loop self-sustaining hydroponic farms.

The second Metaphor sub-concept is Metaphora. An infrared handheld scanner with a silicon transdermal patch, Metaphora is for patients who can’t consume food.

“If a patient cannot eat, for medical reasons, or they do not want to eat, the patient is given a Metaphora transdermal patch to wear,” Associate Professor Thong says.

Metaphora, infrared handheld scanner and transdermal nutrient patch

A nurse applies a clean, recharged patch filled with nano-encapsulated biodegradable nano-nutrients. The handheld infrared scanner is used to scan the patient’s nutrition levels and to detect deficiencies. Patches provide the required amount of nutrition through infrared heat activated nanoparticles.

“In line with CERN philosophy, the A3 CBI is an open innovation platform. The details of these concepts and others developed in the Design Factory Global Network are always publicly shared,” says Associate Professor Thong.